Continuous Insulation Using Polyiso Wall Sheathing

Introduction

This text refers to the technical bulletin on Continuous Insulation usine Polyiso Wall Sheathing of the PIMA association.

National model energy codes are advancing the way we approach building commercial and residential exterior walls by emphasizing the use of continuous insulation systems, which provide a continuous insulation layer over an entire wall, not just in the wall cavities. Building science experts have known for some time that continuous insulation is a very effective way to insulate building envelopes for energy savings. Now, modern building codes are putting this knowledge into practice.

What is continuous insulation?

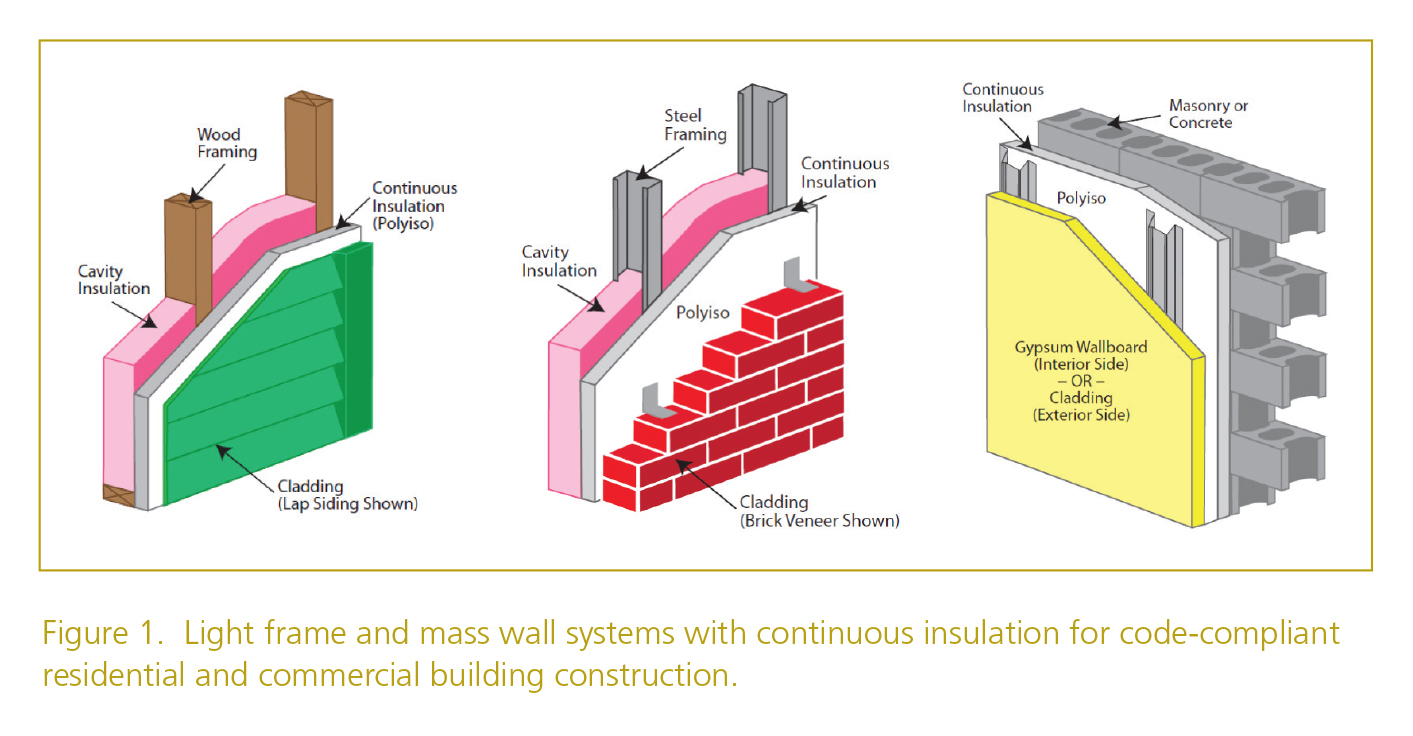

Continuous insulation is defined as “insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings. It is installed on the interior, exterior, or is integral to any opaque surface of the building envelope.”1 Figure 1 shows several common applications of continuous insulation.

As shown in Figure 1, continuous insulation can be used with variety of wall structural systems and cladding materials such as cement board, PC stucco, wood lap, brick veneer, stone, and vinyl siding. Furthermore, continuous insulation can be placed on the interior or exterior side of the wall with proper consideration of climate-dependent moisture vapor control code requirements. For example, it is common to place continuous insulation on the inside face of foundation walls and also above-grade masonry walls, which is considered a typical practice in Florida where the exterior masonry wall face is coated with stucco or parging. Finally, it is possible to use continuous insulation alone to meet energy code without any cavity insulation for the ultimate “warm wall” design.

What does it do?

Continuous insulation can serve several important functions in a high-performing wall system including continuous thermal insulation, moisture vapor control, water resistive barrier and air barrier. These capabilities provide the following benefits:

-

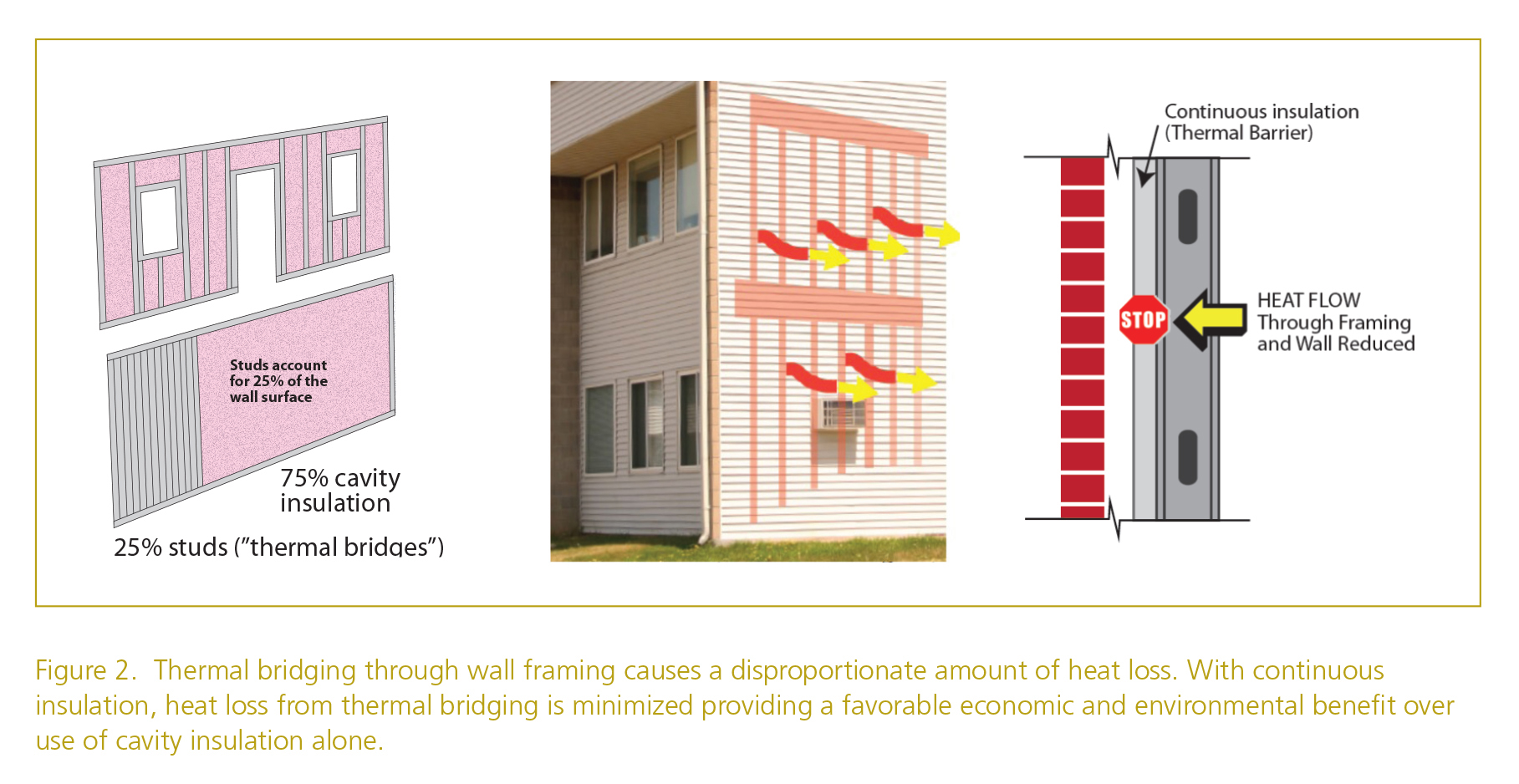

- Increased thermal performance

By blocking thermal bridging, a continuous insulation system increases the overall thermal performance of a wall assembly and a building. - Reduced operating costs

Continuous insulation keeps energy and heat loss to a minimum, increasing the building’s energy efficiency and leading to lower monthly operating costs. - Reduced air infiltration and exfiltration

Continuous insulation with taped or sealed joints restricts air movement through the wall, helping to further reduce building heat loss. - Reduced risk of water condensation and moisture intrusion

Continuous insulation is a very moisture-resistant system, guarding the thermal and structural performance of the building. - Efficient installation

When used as a multi-function sheathing, continuous insulation can simplify the steps to construct a code-compliant wall assembly. - Dimensional Stability

Polyiso insulation has excellent dimensional stability and meets ASTM C1289 Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board.

- Increased thermal performance

Get-R Done TIP

Specify continuous insulation to serve multiple wall assembly functions, including energy code R-value compliance and the building code’s water resistive barrier (WRB) requirements. A continuous insulation WRB also provides an effective air barrier required by the energy code when taped sheathing joints are used. Be sure to install continuous insulation in a code-compliant overall wall assembly and follow manufacturer instructions and approved building plans.

Why you need it

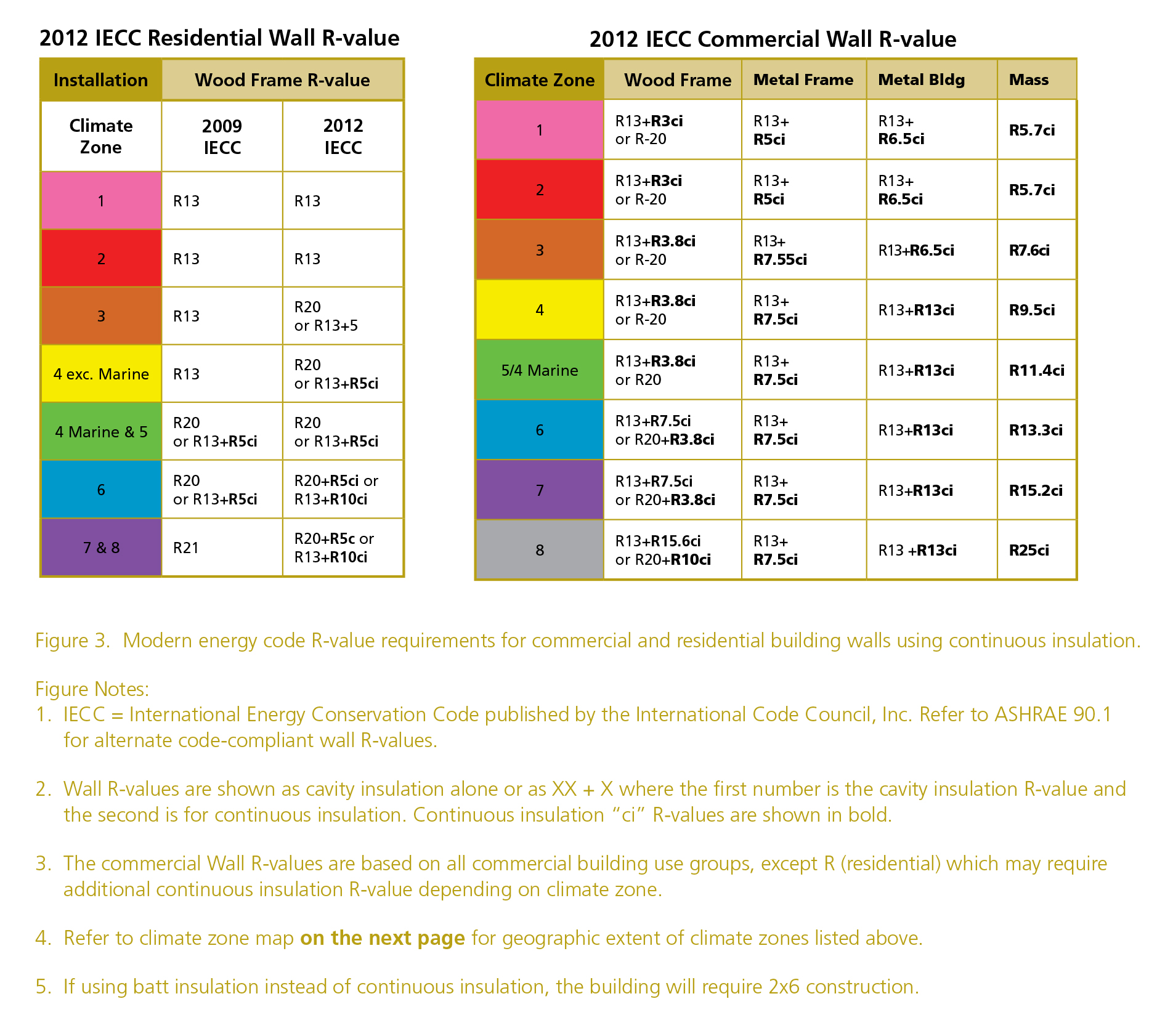

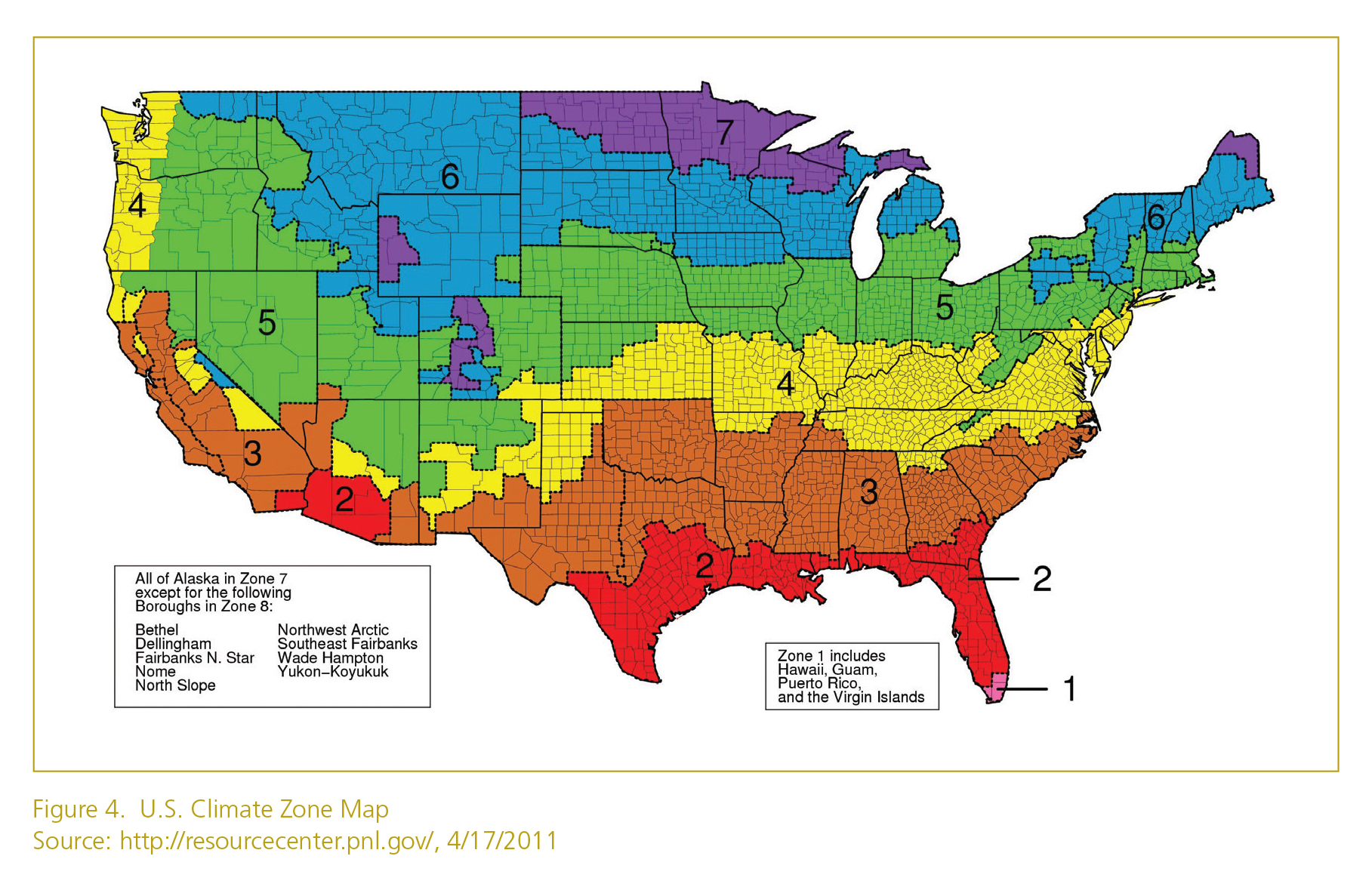

As noted above, continuous insulation is needed to achieve high-performance wall assemblies. More importantly, it will be increasingly needed for energy code compliance (see Figure 3 below) as mandated to all states that have accepted federal economic stimulus funds. As newer national, state and local energy codes continue to place a greater emphasis on energy conservation, code developers and experts are turning to a greater use of continuous insulation for its known ability to reduce thermal bridging and increase energy efficiency at reasonable first cost while providing operating cost paybacks through reduced energy bills. Examples of modern energy code requirements for wall insulation using continuous insulation are shown in Figure 3. A color coordinated U.S. climate zone map is provided in Figure 4. Voluntary energy efficiency programs, such as the EPA’s EnergyStar program, have been encouraging and rewarding use of continuous insulation for some time. Model building and energy codes are finally catching up with this best practice for wall insulation.

Why choose polyiso?

Not all continuous insulation materials are equal. For example, the following two points demonstrate the superior value of polyisocyanurate insulation for continuous insulation on exterior wall assemblies:

- The highest R-value in class Polyisocyanurate continuous insulation has at least 20% to 70% greater R-value per inch than other common types of continuous insulation (rigid foam plastic sheathing). This means more energy savings and/or more manageable wall thicknesses. With thinner, energy efficient walls using polyisocyanurate continuous insulation, there will be more usable floor area within the footprint of the building. Also, cladding materials are more easily installed over the thinner continuous insulation achievable by use of polyisocyanurate sheathing. Simply put, there’s more bang for the buck with polyisocyanurate continuous insulation wall sheathing.

- Code-compliant wind pressure resistance Foam sheathing industry testing2 for code compliance at an independent laboratory has demonstrated that polyisocyanurate continuous insulation provides code-compliant wind pressure resistance for exterior wall sheathing.

- Wall moisture-resistant design flexibility Polyiso is available with a variety of facer types to provide water resistive barrier performance or to provide water vapor permeability as required by climate or code-compliant wall design preferences.

- Fire Test Compliant Polyiso, a thermoset material, stays intact during fire exposure in the ASTM E84 or “Tunnel Test.” It forms a protective char layer and remains in place during this test, thereby meeting all building code requirements and contributing to a fire-safe building. For more information on polyiso’s performance in fire tests, consult the Technical Bulletins section of polyiso.org.

While not all continuous insulation materials are equal, continuous insulation as a product class offers many advantages over other types of wall sheathing. Some of these advantages were discussed earlier. For more information on the advantages of continuous insulation over other non-continuous insulation wall sheathing choices, refer to “Overview of Wall Sheathing Options: The Value of Foam Sheathing as a Wall Covering.”3

REFERENCES

1ASHRAE 90.1-2007, Energy Standard for Buildings Except Low-Rise Residential Buildings, American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc., Atlanta, GA.

2http://www.foamsheathing.org/ (4/17/2011)

3http://www.foamsheathing.org/tech_info/OverviewofWallSheathingOptions.pdf?PHPSESSID=5a3ak3njtrrqgtiuef6t77h0k0 (6/15/2011)