Reduction of the Global Warming Potential (GWP) of SOPRA-XPS

January 1, 2021, marked the entry into force of new regulations from Environment and Climate Change Canada (ECCC), specifically an amendment to the Ozone-Depleting Substances and Halocarbon Alternatives Regulations.

As part of the legacy of the well-known Montréal Protocol of 1987 on the protection of the ozone layer adopted by 197 signatory countries, including Canada [1], these regulations cover and limit the use of halocarbons with a Global Warming Potential (GWP) of more than 150 [2]. Like for many other products manufactured or imported in Canada, these regulations are intended in particular for manufacturers of plastic-foam insulating materials using the ingredients covered because of their GWP.

SOPREMA made major changes to its SOPRA-XPS line of extruded polystyrene insulation in order to exceed these new requirements. These changes have significantly reduced the greenhouse gas (GHG) emissions associated with these panels throughout their lifecycle.

Read this article to learn more about reducing the GWP and GHG emissions within the SOPRA-XPS line of insulating materials, a new generation of products that combine performance and environmental safety.

Definition of the Main Concepts

Climate change, also called global warming, is recognized internationally. All over the world, the intensification and increase in the recurrence of events – such as floods, forest fires, heat waves, and precipitation – reveal the negative effects of the phenomenon. Global warming is largely due to the greenhouse effect, a phenomenon caused by the accumulation of gases in the atmosphere that form a barrier and trap solar radiation as well as heat. For several decades, international conferences on climate and the environment have given rise to numerous discussions and commitments between countries, which have led to targets for reducing GHG emissions. As this article shows, the situation is also leading some organizations to reduce and mitigate their GHG emissions.

When talking about the carbon impact of an activity, a product or a service, several terms and concepts are used on a regular basis. Here are some explanations regarding global warming potential (GWP) and greenhouse gas (GHG) emissions.

Global Warming Potential (GWP)

The GWP generally applies to the ingredients or substances used in a product. This index helps to compare the global warming impact of different gases such as those used as blowing agents in insulating foam. The GWP of a gas measures the impact that one tonne of its emissions will have on climate change over a 100-year period compared to the emissions from one tonne of carbon dioxide (CO2). In other words, the higher the GWP, the greater the gas contributes to global warming. [3]

Greenhouse Gas (GHG) Emissions

Greenhouse gas emissions refer to the main gases contributing to global warming due to their higher concentration in the atmosphere. These include water vapour, carbon dioxide, nitrous oxide, methane, and ozone. There are also a number of completely human-produced GHGs in the atmosphere, such as halocarbons and other substances containing chlorine and bromine. To simplify the quantification of GHG emissions and reporting of results, the carbon dioxide equivalent (CO2 eq.) is the reference unit used. This corresponds to the sum of the emissions of all the GHGs under the same unit [3]. It is also called carbon impact.

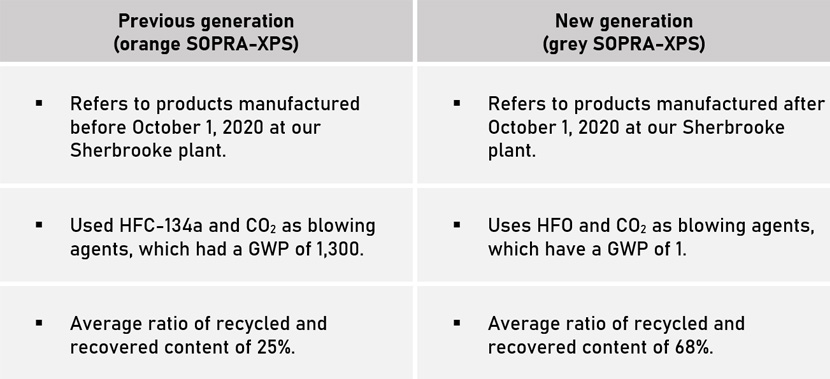

Changes to the SOPRA-XPS Line

In order to fully explain the changes made to the SOPRA-XPS line, two distinct categories are shown, namely the previous generation (orange panels) and the new generation (grey panels). The differences between these two generations are explained below:

Reducing the Global Warming Potential (GWP)

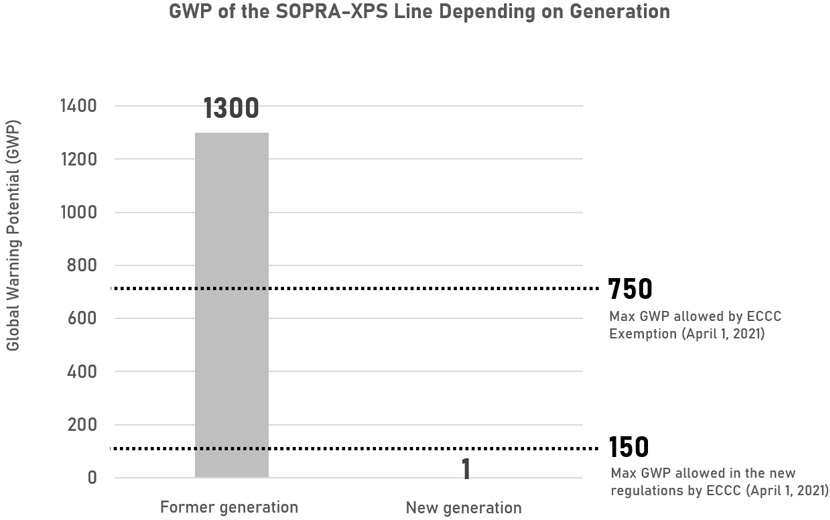

The new formula of the SOPRA-XPS line mainly substitutes the use of HFC-134a (GWP of 1,3001) with a blowing agent of the HFO type (GWP of 1). As regards the impact on the GWP of the blowing agent, this is a reduction of at least 99.92%.

As illustrated below, the new SOPRA-XPS generation uses a blowing agent that has a GWP that is 99.33% lower than a GWP of 150, which is the maximum threshold allowed by Canadian regulations as of January 1, 2021. Despite these new regulations, three other manufacturers of extruded polystyrene insulation panels have obtained an exemption from ECCC allowing them to use, effective January 1, 2021, blowing agents with GWP limited to 550 or 750, as the case may be. The permit duration varies between one and two years [5].

1The GWP of HFC-134a is derived from the Assessment Report 5, from the IPCC organization [4]. The subsequent edition (Assessment Report 6) indicates a slightly higher GWP (around 10%). This difference is insufficient to influence the conclusions presented here. Before January 1, 2021, all manufacturers of extruded polystyrene insulation primarily used blowing agents with a GWP greater than 1,000.

Lifecycle Analysis (LCA)

Overall, changes made to the SOPRA-XPS line have significantly reduced the absolute direct and indirect GHG emissions associated with SOPREMA’s manufacturing process.

In order to better understand the environmental impacts of SOPRA-XPS, a lifecycle analysis (LCA) was carried out by an independent third party. The results of the LCA were summarized in an environmental product declaration (EPD) specific to the SOPRA-XPS line and published in January 2022 [6]. Although such a publication addresses six categories of impact, this article only addresses the impact of the product on the GWP, i.e. the GHG emissions (or the carbon impact) attributable to SOPRA-XPS over its entire lifecycle.

The comparison of the carbon impact between the different extruded polystyrene insulating materials is based, on the one hand, on verified data from the SOPRA-XPS EPD and, on the other hand, on the results of the EPD published by the manufacturers of equivalent products with production sites in Canada, which are Owens Corning [7] [8] and Dupont [9] [10]. All of these EPDs include the following:

- The results of the GWP’s environmental impact are expressed in CO2 kg per unit of reference. This unit is defined as one square metre insulated at a thickness providing an RSI thermal performance of 1. For extruded polystyrene insulating material, this thickness is 25 mm to 29 mm.

- The results disclosed encompass the entire product lifecycle, from its production (including raw materials) to its disposal. The duration of the insulation panel is considered equivalent to that of the building, which is set at 75 years. The EPDs comply with Standards EN 15804, ISO 14025, and ISO 2193.

Carbon Impact of SOPRA-XPS’ Full Lifecycle

The results published in the EPD show that, over its entire lifecycle, 1 m2 of SOPRA-XPS manufactured at the SOPREMA plant in Sherbrooke, Québec (Canada) and installed at a thickness providing an RSI value of 1, will emit 2.06 kg of CO2 eq. This is the lowest carbon impact of all XPS-type insulating materials. The substitution of the blowing agent is the main cause of such an impact. The use of up to 63% recycled polystyrene as well as the recovery of cut-outs and waste have also helped to keep GHG emissions at one of the lowest levels amongst all types of insulating materials combined.

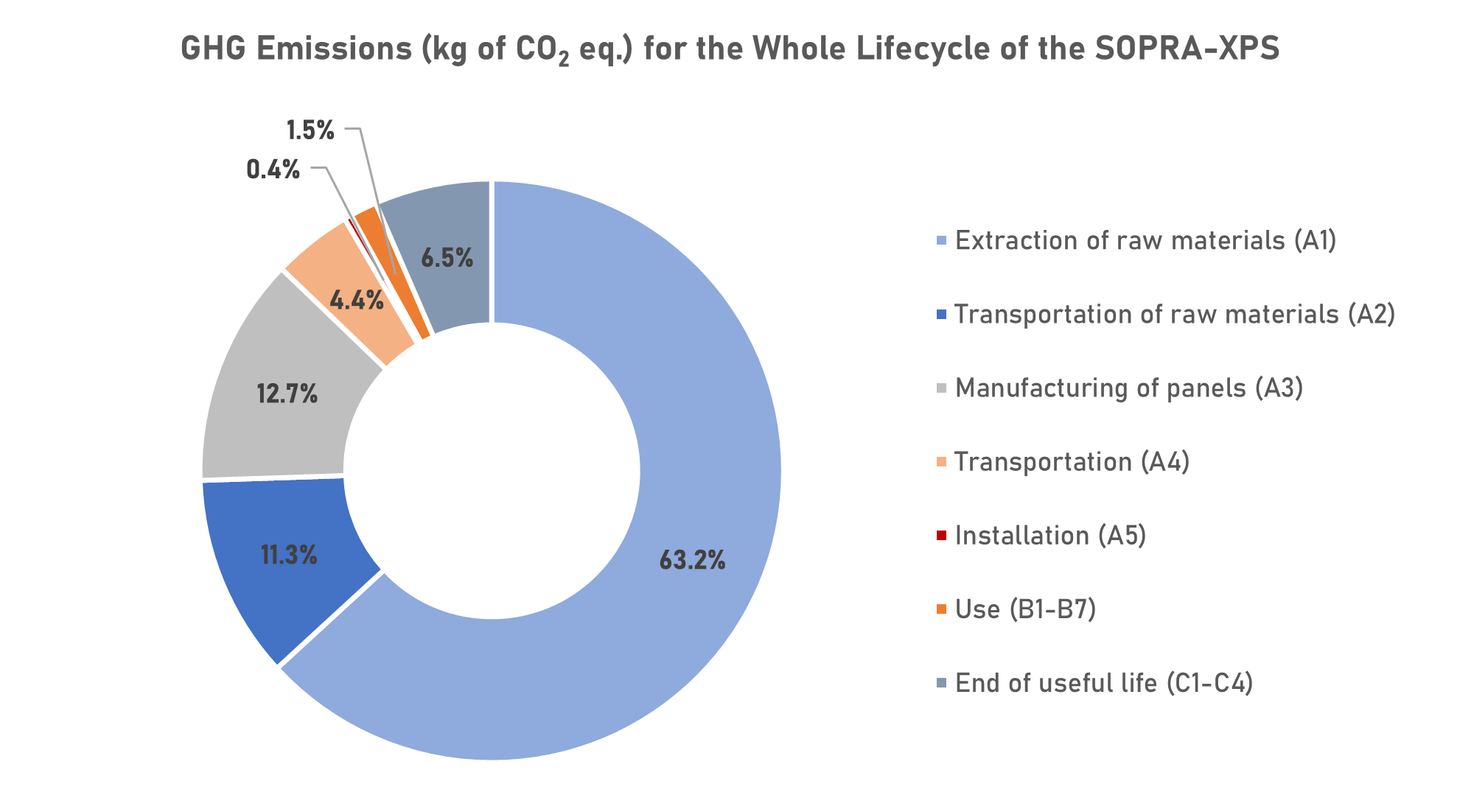

As the next graph shows, each of the stages of the product’s lifecycle contributes differently to the total emissions of SOPRA-XPS.

The results show that the lifecycle stage with the greatest impact in terms of GHG emissions is the production of raw materials, i.e. Module A1 (63.1%). The main contributor to this module is the production of virgin polystyrene beads. Surprisingly, this element constitutes more than 68% of Module A1 (and 43% of the total impact of SOPRA-XPS over its entire lifecycle) despite the fact that virgin polystyrene represents only 20% of the insulating panel’s mass. This is followed by the stage of manufacturing the insulating panel (Module A3), which constitutes 12.7% of the total impact, then by Module A2 (stage of raw materials transportation to our factory) with a contribution of 11.3%. In the latter case, the transportation of recycled polystyrene is the main contributing element to the module and is followed by the stages surrounding the end of the products’ useful life (Modules C1 to C4), which correspond to 6.5% of the carbon impact. The stages of transporting the panels to our customers (Module A4), their use (Modules B1 to B7), and their installation (Module A5) bring up the rear with a contribution of less than 5% for each.

Full Carbon Impact of the Lifecycle of Other XPS Insulating Materials Made in Canada

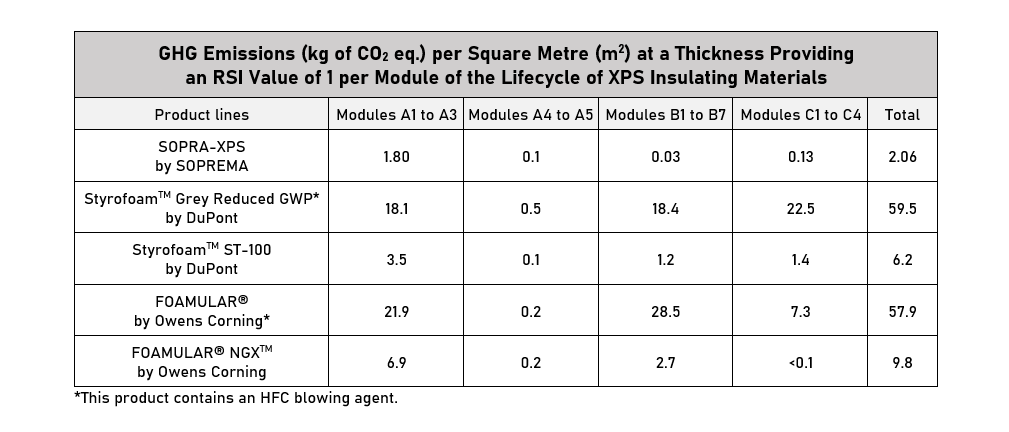

Over its entire lifecycle, the new SOPRA-XPS generation produces the lowest level of GHG emissions. The following table compares the emission levels reported in each of the EPDs for the XPS products. As the EPDs of DuPont and Owens Corning products show the combined impacts of Modules A1 through A3, the sum of these modules is presented here.

Unsurprisingly, the differences between the products are found in the modules where there is a loss of blowing agent. The halocarbon-based blowing agents diffuse out of the polystyrene foam and are emitted in the air during the lifecycle of the insulation panel. It is considered that 7% of the total quantity of blowing agent is emitted during the manufacturing stage of the insulation panel (Module A3), 70% during the use phase (Module B1), and 23% during the end-of-life stage (Module C4). This scenario is based on the documented release rate [11] of the HFC-134a blowing agent, which was also attributed to the HFO-1234ze agent for SOPRA-XPS.

It is therefore normal to note that the two XPS products containing an HFC blowing agent indicate much higher amounts of GHG emissions in the modules concerned. For the other three products, the difference is less significant and is mainly explained by the presence of a large proportion of recycled polystyrene in SOPRA-XPS. These three products will remain available on the Canadian market after the expiration of the special permits issued by ECCC.

Carbon Impact at the Scale of a Building

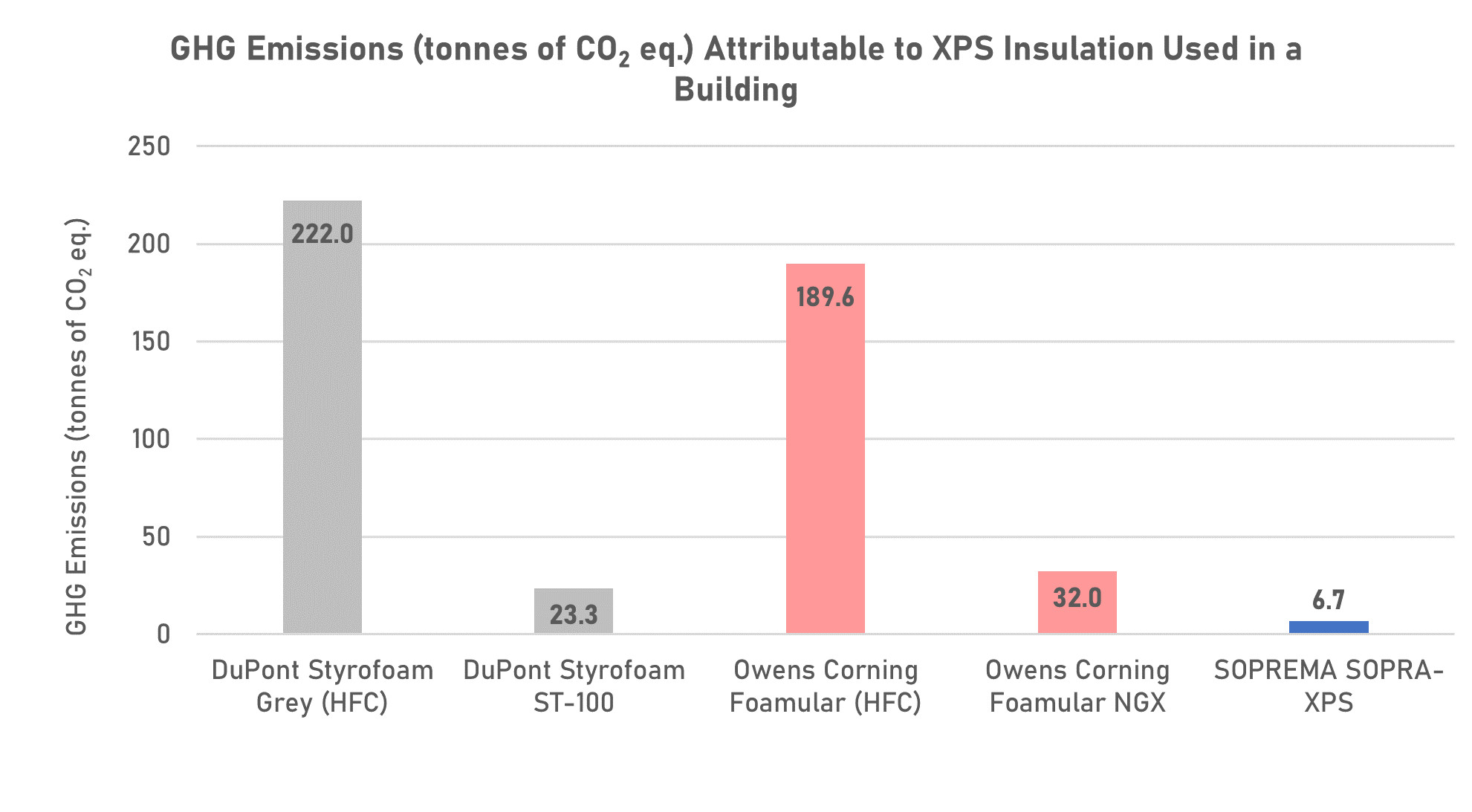

In order to better illustrate the impact of the product on the scale of a building, a real project corresponding to a typical construction application method was analyzed.

The results of the various EPDs were applied to a construction project for a building for which the client used extruded polystyrene (XPS) insulation panels to ensure the thermal insulation of the exterior walls and the concrete slab. The senior citizen centre of 4,375 m2 (47,092 ft2) on three floors, built in 2021 in Québec, used a total volume of 94.4 m3 of SOPRA-XPS insulating material.

Carbon Impact Relating to the Complete Lifecycle of XPS Insulating Materials at the Scale of a Building

The results of the various EPDs were applied to a construction project for a building for which the client used extruded polystyrene (XPS) insulation panels to ensure the thermal insulation of the exterior walls and the concrete slab. The senior citizen centre of 4,375 m2 (47,092 ft2) on three floors, built in 2021 in Québec, used a total volume of 94.4 m3 of SOPRA-XPS insulating material.

- Exterior walls: Use of 750 SOPRA-XPS 20 panels, 2 in thick and 2 ft × 8 ft in size, with a total volume of 56.6 m3.

- Concrete slab: Use of 500 SOPRA-XPS 30 panels, 2 in thick and 2 ft × 8 ft in size, with a total volume of 37.8 m3.

As shown in the next graphic, the SOPRA-XPS insulating material used in this project will emit a total of 6.7 tonnes of CO2 eq. over its entire lifecycle. In comparison, the product StyrofoamTM Grey Reduced GWP by DuPont would emit a total of 221.9 tonnes of CO2 eq., or 215 tonnes of CO2 eq. more than SOPRA-XPS if it had been installed on the same project. A similar observation can be made for products such as FOAMULAR® by Owens Corning, which has additional emissions of 190 tonnes of CO2 eq. As for other products displaying a lower impact, Styrofoam ST-100 by DuPont would emit 23.3 tonnes of CO2 eq., and FOAMULAR® NGXTM, 32 tonnes of CO2 eq. at the scale of a building. That is respectively 17 and 25 tonnes of CO2 eq. more compared to SOPRA-XPS.

Some would argue that the difference between the GHG emissions of the various types of XPS insulating materials are minor when compared to the amounts of GHGs that are saved during the operation of the building due to the presence of the insulating materials. Although this is true, once a thermal performance target is established for the building, the R-value of the insulating materials installed on that building is fixed. The quantity of GHG emissions linked to the operation of the building therefore becomes a constant which is independent of the choice of insulation type.

The insulating material will, however, have a direct impact on the embodied carbon emissions of the materials chosen for construction. This is why it is preferable to choose insulating materials with a lower carbon footprint such as SOPRA-XPS. Even the smallest gain must not be overlooked.

References

[1] Environment and Natural Resources Canada (2019). The Montréal Protocol: Protecting the Ozone Layer and Tackling Climate Change.

[2] Canadian Environmental Protection Act (1999). Ozone-Depleting Substances and Halocarbon Alternatives Regulations. DORS/2016-137.

[3] Intergovernmental Panel on Climate Change [IPCC] (2013). Glossary ‒ Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the IPCC.

[4] Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change [Stocker, T.F., et al.], Cambridge University Press.

[5] Environment and Natural Resources Canada (2021). Authorizations for Ozone-Depleting Substances and Hydrofluorocarbons: Companies with Essential Purpose Permits for Foam and Foam Products.

[6] ASTM International (2021). Environmental Product Declaration – SOPRA-XPS® Extruded Polystyrene Insulation Board. Registration Number EPD-293.

[7] UL Environment (2019). Environmental Product Declaration (EPD) – FOAMULAR® XPS Insulation. Owens Corning. Declaration Number 4788721182.101.1.

[8] UL Environment (2021). Environmental Product Declaration (EPD) – FOAMULAR® NGXTM XPS Insulation. Owens Corning. Declaration Number 4789639125.101.1.

[9] UL Environment (2021). Environmental Product Declaration (EPD) – North American Grey Reduced GWP StyrofoamTM Brand XPS Products. DuPont. Declaration Number 4789559274.102.1.

[10] UL Environment (2021). Environmental Product Declaration (EPD) – Styrofoam® Brand ST-100 Products. DuPont. Declaration Number 4789868895.101.1.

[11] American Carbon Registry (2016). Emission Reduction Measurement and Monitoring Methodology for the Transition to Advanced Formulation Blowing Agents in Foam Manufacturing and Use. Version 1.0. Table 5.

StyrofoamTM is a registered trademark or trademark of E.I. du Pont de Nemours and Company or its affiliates. FOAMULAR® and NGXTM are registered trademarks or trademarks of Owens Corning or its affiliates.

©2021 SOPREMA. All rights reserved. SOPREMA, the SOPREMA logo and SOPRA-XPS are registered trademarks or trademarks of SOPREMA HOLDING or its affiliates.